Bosch EDC 17 Service Manuals. Wiring Diagram. Pinout

Professional technical manual covering the EDC 17 engine management system used in modern Euro 5 and Euro 6 diesel vehicles.

- Complete wiring diagrams

- Detailed schematic diagrams for all components

- Pinout of control units (ECU), sensors, valves and actuators

- Diagnostic tables and description of typical faults

- System operation algorithms: injection, turbocharging, EGR, DPF, SCR (AdBlue)

- Information on CAN, LIN protocols and diagnostic interfaces

For commercial vehicles and trucks (MAN, DAF, Scania, Iveco):

- EDC17CV41

- EDC17CV44

- EDC17CV52

- EDC17CV54

- EDC17CP64

- EDC17C49

- EDC17C90

| Common Rail system with accumulator fuel injection system EDC17 | Download |

| EDC 17 (D08 Common Rail Engine) Pinout Service Manual | Download |

| Electronic Diesel Control EDC 2001 | Download |

| D20 D26 EDC Service Manual | Download |

| EDC 17 Engine and peripherals. Fault finding | Download |

| EDC 17 For H-Series BSIII and BSIV Engines | Download |

| EDC 17 system for Neptune N4 CRS BSIV engines | Download |

| FPT Iveco Electrical EDC17CV41 | Download |

| NT Bosch Edc17cv41 Irom TC1797 Pinout | Download |

| Pinout Bosch EDC17CV41 irom TC1797 allbrand | Download |

| Bosch Edc17cv52 Irom Tc1797 Deutz 1033 | Download |

| Pinout Bosch EDC17CV52 irom TC1797 Deutz | Download |

| Bosch MEDC17 Bootloader | Download |

| Bosch Edc17cp52 Irom Tc1797 Iveco 1040 | Download |

| Pinout Bosch EDC17C49 irom TC1797 Iveco | Download |

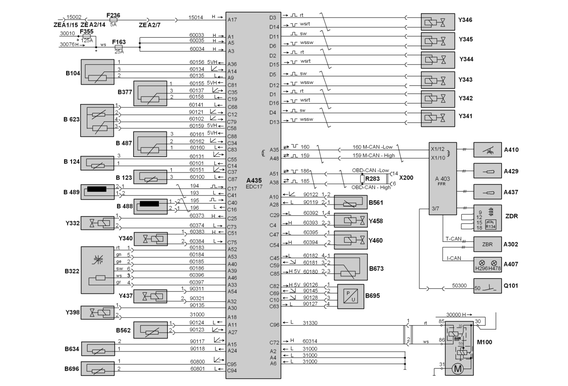

A302 Central Computer 2

A403 Vehicle Control Computer

A407 Instrumentation

A410 Accelerator Pedal

A429 Cruise Control Switch

A435 EDC17 Control Unit

A437 Continuous Brake Pulse Switch

B104 Oil Pressure Sensor

B123 Charge Air Temperature Sensor

B124 Coolant Temperature Sensor

B322 Lambda Sensor

B377 Fuel Pressure Sensor

B487 Fuel Rail Pressure Sensor

B488 Incremental Speed Sensor

B489 Segment Speed Sensor

B561 Exhaust Gas Temperature Sensor Before Filter

B562 Exhaust Gas Temperature Sensor After Filter

B623 Boost Pressure/Temperature Sensor

B634 Exhaust Gas Temperature Sensor After SCR Catalytic Converter

B673 E-AGR Cylinder Travel Sensor

B695 Exhaust Gas Differential/Relative Pressure Sensor

B696 EGR Temperature Sensor EDC17

F163 Engine Control Fuse (Terminal 30)

F236 Fuse, Engine Control (Terminal 15)

F355 Main Fuse 30-2

H296 EDC Indicator Lamp (Malfunction)

H478 Exhaust System Indicator Lamp (MIL)

M100 Starter

Q101 Steering Wheel Lock

R134 EDC Resistor Group

R283 HD-OBD-CAN Terminator

X200 Diagnostic Socket

Y332 Fuel Proportional Valve

Y340 Turbocharger 1 Pulse Valve

Y341 Injector 1 Cylinder

Y342 Injector 2 Cylinder

Y343 Injector 3 Cylinder

Y344 Injector 4 Cylinder

Y345 Injector 5 Cylinder

Y346 Injector 6 Cylinder

Y398 CRT Wastegate Solenoid Valve

Y437 Coolant Solenoid Valve

Y458 E-AGR Proportional Valve

Y460 E-AGR/EVBec Shut-off Valve

ZDR Intermediate Speed Connector

1 CP 3.3 NH quantity-controlled high-pressure pump

2 Fuel proportional valve (Y332)

3 Fuel rail pressure sensor (B487)

4 Pressure limiting valve (DBV 4) integrated in the fuel rail

5 Injectors (Y341 – Y346)

6 High-pressure accumulator (fuel rail)

7 Flame glow plug (R100)

8 Flame start solenoid valve (Y100)

9 Fuel pressure sensor (B377)

10 Hand feed pump with pre-filter

11 KSC fuel assembly

12 HCI metering unit (A1081)

13 HCI injection unit

Main problems of Bosch EDC 17:

1. Clogged diesel particulate filter (DPF)

Cause: short trips, bad fuel, faulty temperature or pressure sensor.

Symptoms: loss of power, regeneration does not start, DPF error.

Often associated with incorrect operation of EDC 17 algorithms.

2. AdBlue / SCR system failures

Problems with the dosing pump, heater, NOx sensors.

Errors: P20E8, P204F, P2200, etc.

Can lead to the launch of the "power limitation mode" (derate).

3. EGR system failures

EGR valve jamming, leaks, position sensor errors.

Check Engine call, overheating, unstable idling.

4. Fuel pressure sensors / Rail / MAP

Often fail after 200-300 thousand km.

Lead to difficult starting, traction failures, injection errors.

5. Control unit (ECU) malfunctions

Internal memory errors, software failures, moisture damage.

Often accompanied by unstable CAN bus operation.

Firmware failure is possible after incorrect chip tuning.

6. CAN/LIN bus errors

Loss of communication with other modules (ABS, TCM, BCM, etc.).

Reason: line break, connector oxidation, power supply problems.

7. Regeneration hang-up / algorithm failures

During long-term driving under partial load conditions.

EDC 17 may "not see" the conditions for DPF regeneration.

All content on TruckFixDiagn.com is taken from free sources and is also freely distributed. We do not sell repair manuals. Our goal is to help you find all available technical documentation in one place.

The site administration does not bear any responsibility for illegal actions, as well as any damage incurred by copyright holders.